This was 2371D when I started the project in May 2000 I bought the car in 1982 and it was built into a rally car. I drove it for about 3 years and then it was left in my friends yard till 1999.

The shell was completely stripped and all parts removed for restoration. When this was done it was found that the bodywork was beyond repair and it was decided that a new one would purchased from Mini Sport at Padiham.

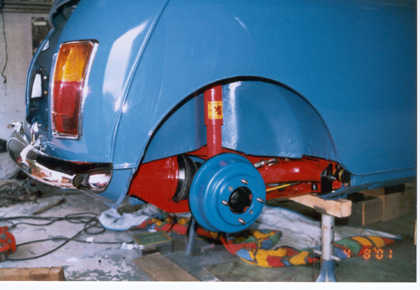

New subframes were purchased and all suspension parts were sandblasted and powder coated in black and maroon. This was completed by October 2002 and the subframes and suspension units were ready to build.

The subframe and suspension components were assembled with polyurethane bushes and all round and stainless steel nuts and bolts. Adjustable tie rods and 1.5 degree negative camber bottom arms were fitted with high-low adjustable suspension units. The front brakes were assembled using 7.5 inch coopers S discs and reconditioned callipers

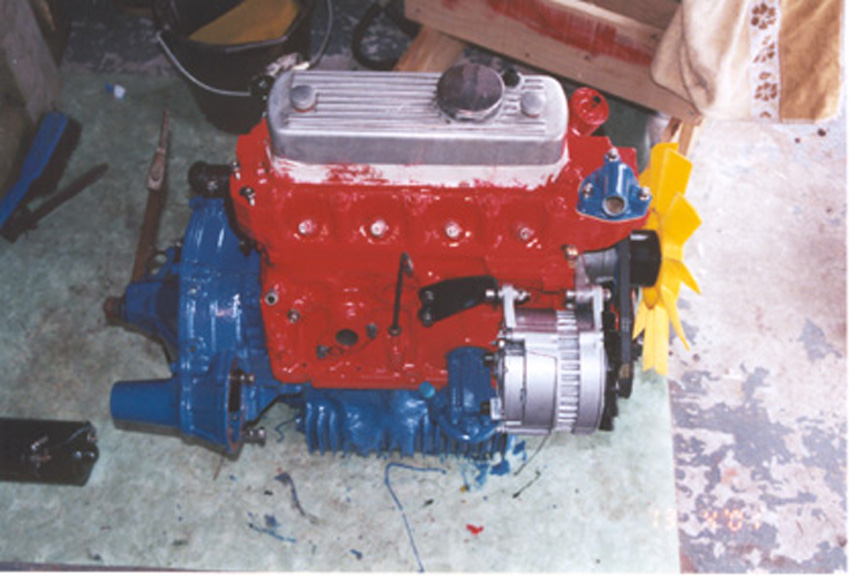

The engine is a 1275 Cooper S and is dated from the late 60’s The gearbox in this picture has been removed and replaced with a remote gear change unit from a 1990 John Cooper Conversion with a Final Drive Ratio 1.105:1

The shell arrived in April 2001 modified to remove the relay mounts on the bulkhead. The shell seams were re-sealed with extra sealer and seals not done by Rover were filled.The underside was prepared with body sealer and sprayed with body filler.

The doors, one purchased new and one including the bonnet were from a scrap yard off a right off. The boot lid was purchased from Mini spares Centre. These were prepared the same as the body shell and inside seams were sealed up with waxol..

The shell was painted in Island Blue with a Snowberry White roof. The doors boot and bonnet were painted seperate off the vehicle and the underneath of the body was painted as well. Next job was to assemble the parts onto the shell

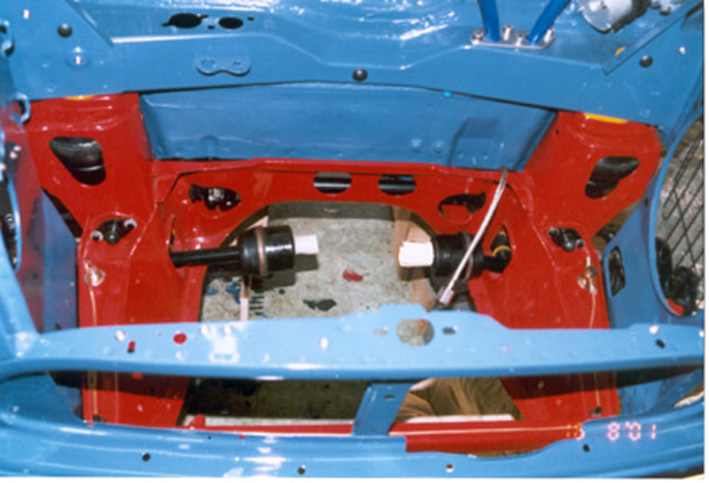

The front subframe and rear subframe were mounted onto the shell to check for positioning before the engine was fitted.

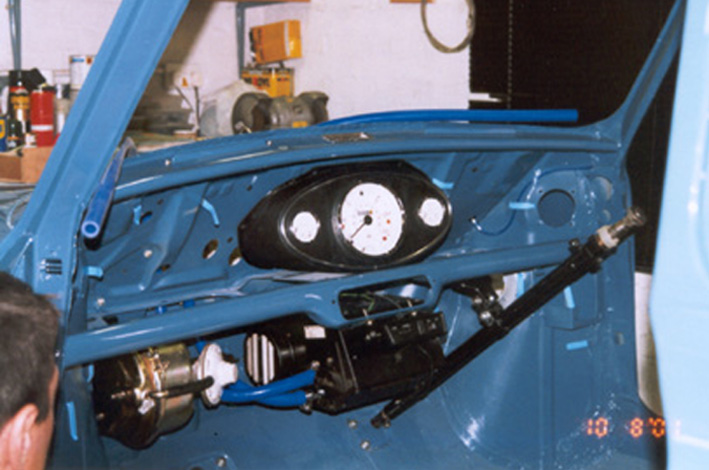

The dash has Smiths Magnolia clocks 130mph speedometer, Oil pressure gauge and water temperature gauge. The servo is mounted below the dash at the passenger side of the vehicle this makes for more room in the engine compartment.

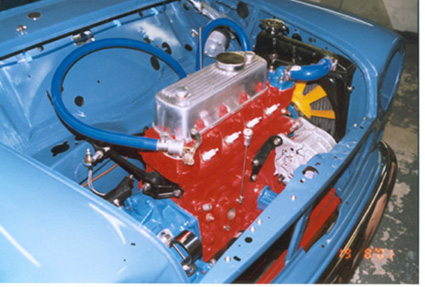

The engine in the engine bay with the radiator and alternator in position the pipes are blue silicon water hoses. The brake pipes were ran before the engine was fitted and also the petrol pipe from front to rear is in stainless steel.

The lights and the bumpers are fitted into position and the petrol tank which is 5.5.gallon in size to leave room in the boot for the electrical fuel pump and the water bottle for the wiper washers.

The rear subframe mounted onto the shell with spax adjustable shocks. With the rear chrome boot lid hinges fitted and ready for the Mk1 boot lid.

The seats were recovered in vinyl in two colours charcoal and grey. The break pipes are ran inside the car and the bias braking valve is mounted below the rear seat. The battery positive lead also runs through in inside of the car from front to rear.

The view of the interior with the front carpet fitted and the handbrake and steering column in place.

This shows the front seats in the car and the blue seat belts that were not fitted to the original car but were a addition to make the safer for the roads.

The interior completed with the front seats and alloy door handles and gear stick knob and mats. This picture shows my John Cooper steering wheel

The lights are all from autojumble and are early 70’s style and this gives the vehicle that older look even though it is a mix and match of various mini versions.

The car completed without the badges or polished by the painter

The car at the first show Dalmeny house Aug 2000